| Parameter | HP200 |

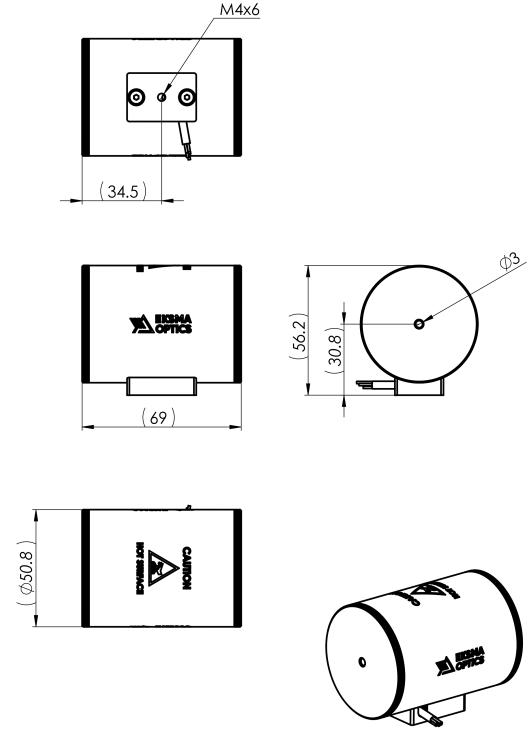

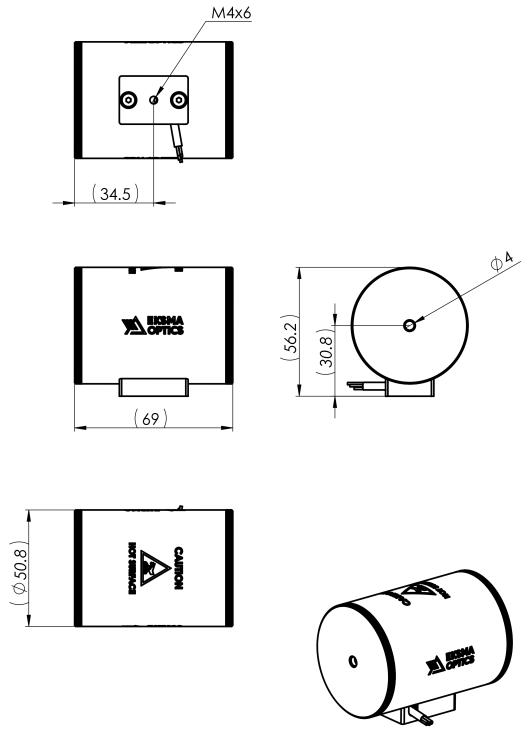

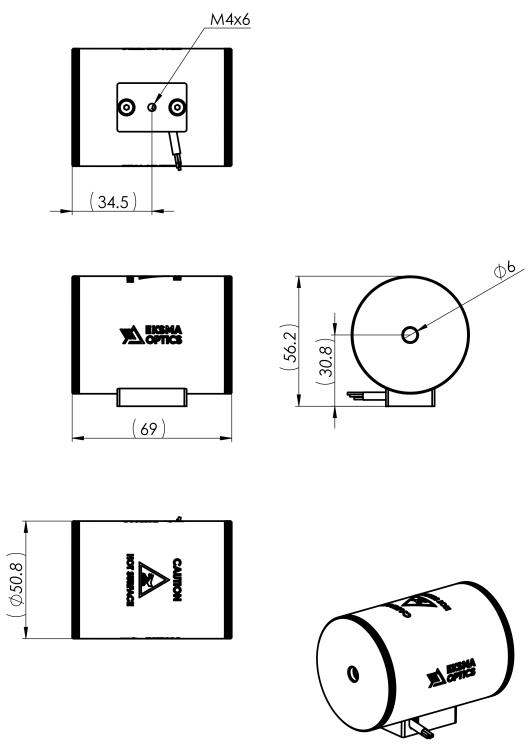

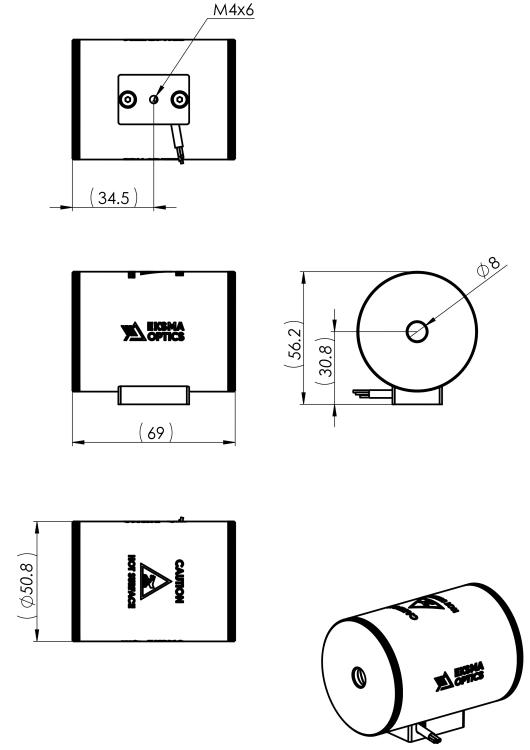

| Crystal dimensions | 3x3x30 … 12x12x30 mm |

| Temperature tuning range | 25 – 220 °C |

| Temperature tuning step | 0.1 °C (knob) |

| 0.001 °C (remote) | |

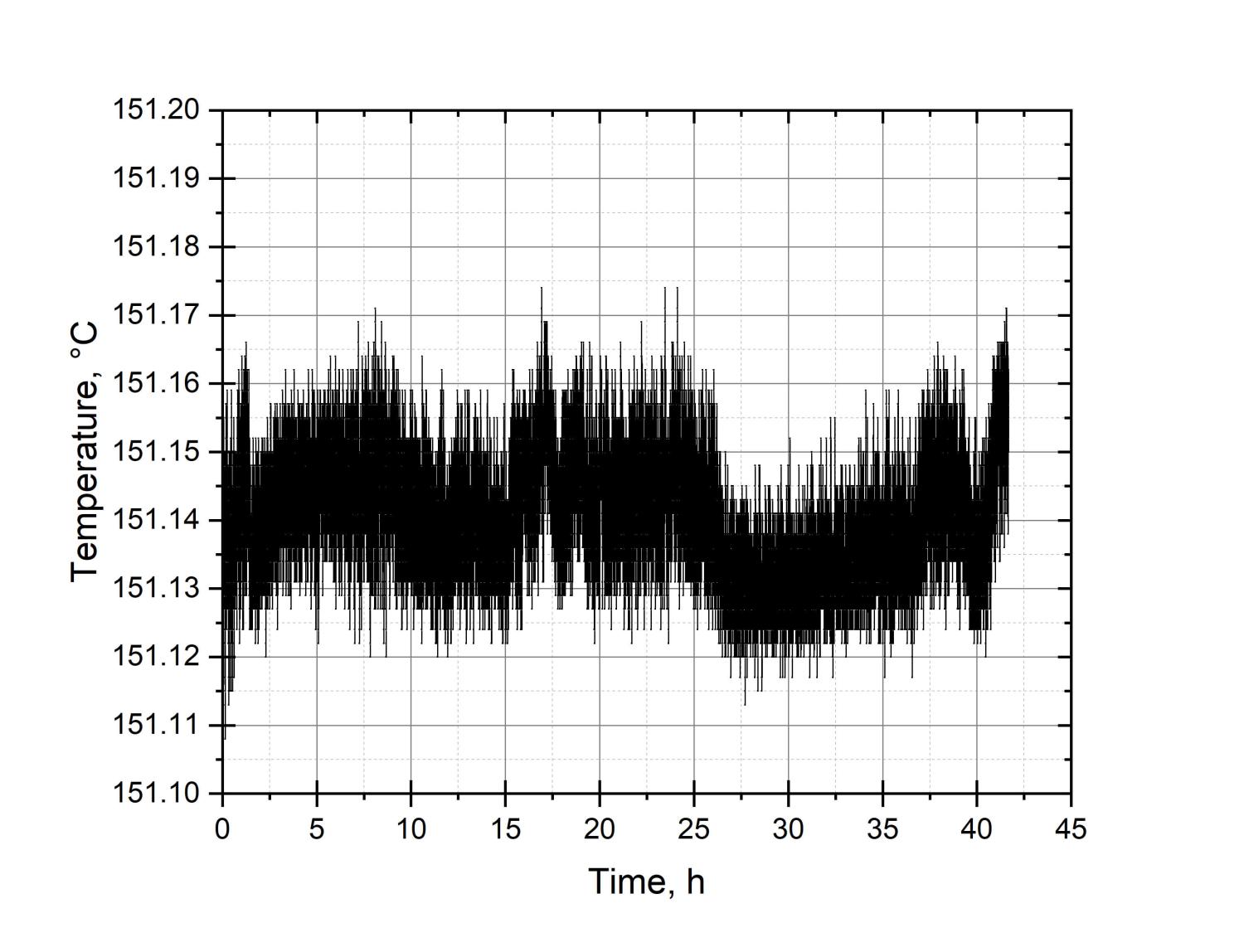

| Long-term stability* | ± 0.03 °C |

| Temperature ramp rate** | 1 – 10 °C/min |

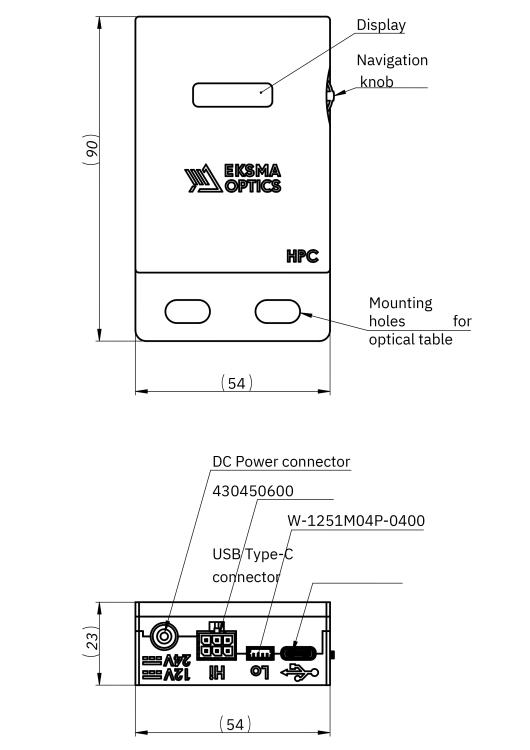

| Power supply | 24 V DC |

| Power consumption | <60 W |

| Oven-to-thermocontroller connector | Micro-Fit 3.0, Dual Row, 6 Circuits |

| Power connector | DC jack, 5.5 x 2.5 mm |

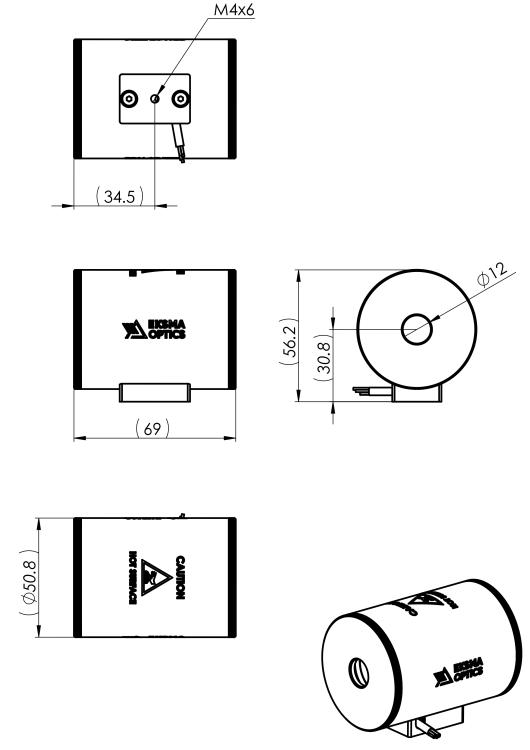

| Thermocontroller dimensions | 54 x 23 x 70 mm |

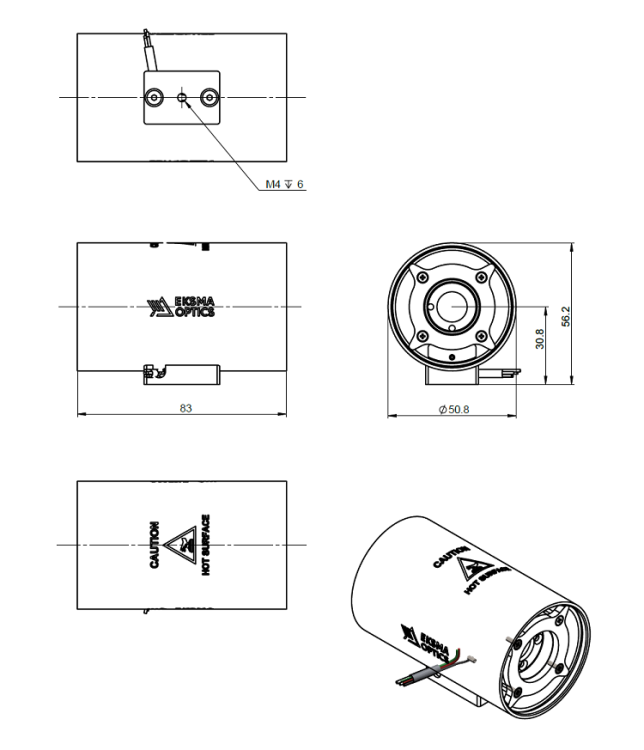

| Oven dimensions | Ø50.8 x 69 mm |

Features:

- Temperature range: 25 - 220 °C

- Suitable for larger crystals:

- Aperture (max): 12 x 12 mm

- Length (max): 30 mm

- High long-term stability

- High temperature homogeneity

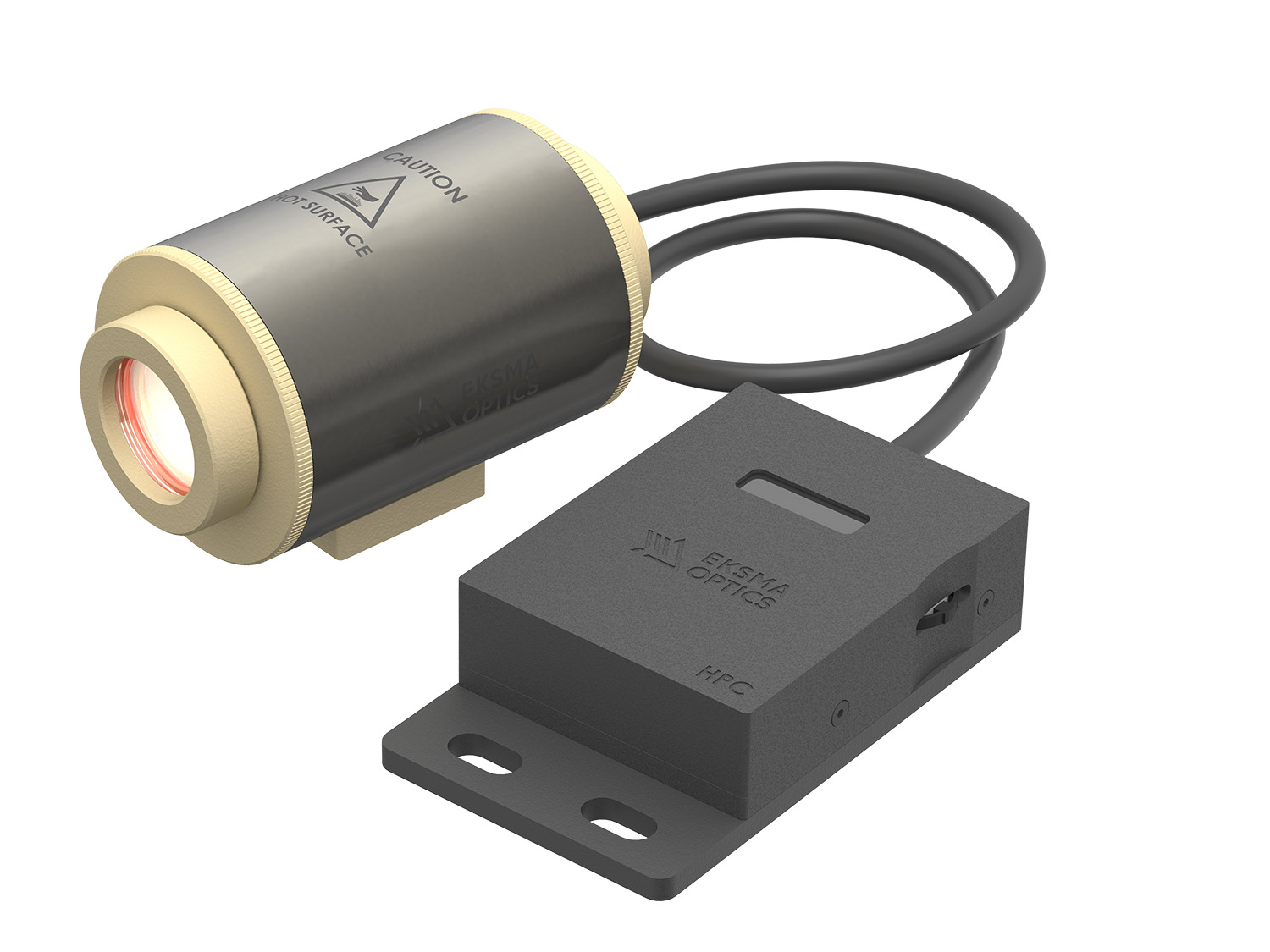

Heatpoint series HP200 oven is the perfect solution for ensuring high-temperature stabilization for temperature-sensitive optical elements such as LBO, DKDP, and CLBO nonlinear crystals. HPC200 allows temperature fine-tuning in 0.1 °C steps for operation from room temperature (~25 °C) up to 220 °C.

Temperature control is an easy task with a set consisting of an HP200 oven and an HPC controller. HPC controller has an OLED display and a knob for easy control of the most frequently tunable parameters, such as temperature and temperature ramp rate. Using HP200 and HPC as a high-temperature kit ensures long-term stability of ±0.03 °C, making HP200 one of the market's most precise and stable ovens.

If you are looking for even more advanced control and monitoring, a kit of HP200 oven with HPC thermocontroller also features USB-C and CAN connections, allowing for easy integration with your existing lab equipment.

We also offer HP200 ovens in sealed design (with anti-reflection coated optical windows) under request. Sealed ovens ensure higher temperature stability, when used with larger aperture nonlinear crystals.

- Address: Dvarcioniu st. 2B LT-10233 Vilnius, Lithuania

- Phone: (+370) 5 272 99 00

- Fax: (+370) 5 272 92 99

- E-mail: info@eksmaoptics.com

.jpg)

.jpg)