| DP-SP-50-3.6-AI | DP-SP-250-2.5-AI | DP-SP-250-3.6-AI | DP-SP-400-1.5-AI | |

| Max / Min HV Operating Voltage | 3.6 kV / 1.8 kV | 2.5 kV / 1.25 kV | 3.6 kV / 1.8 kV kV | 1.5 kV/0.75 kV |

| Maximal HV repetition rate1) | 50 kHz | 250 kHz | 250 kHz | 400 kHz |

| Pulse duration | 15-5000 ns | 15-1250 ns | 15-1250 ns | 15-620 ns |

| HV pulse rise time, typical | <7 ns | <6 ns | <7 ns | <5.5 ns |

| HV pulse fall time, typical | <7 ns | <6 ns | <7 ns | <5.5 ns |

| Output polarity | positive | |||

| HV power consumption | <20 W | <40 W | <75 W | <20 W |

| 12V / 24V power consumption | 1 W | 4.5 W | 4 W | 5.5 W |

| Cooling | water | |||

| DP-SP-600-1.8-AI | DP-SP-600-2.5-Al | DP-SP-1000-1.8-AI | |

| Max / Min HV Operating Voltage | 1.8 kV/0.9 kV | 2.5 kV/1.25 kV | 1.8 kV/0.9 kV |

| Maximal HV repetition rate1) | 600 kHz | 600 kHz | 1000 kHz |

| Pulse duration | 15-400 ns | 15-400 ns | 15-250 ns |

| HV pulse rise time, typical | <6 ns | <6.5 ns | <6 ns |

| HV pulse fall time, typical | <6 ns | <6.5 ns | <6 ns |

| Output polarity | positive | ||

| HV power consumption | <35 W | <100 W | <80 W |

| 12V / 24V power consumption | 7 W | 7 W | 9 W |

| Cooling | water | ||

If alternative aluminum case is required, please add note “option 1” when ordering, for e.g., “Pockels cell driver DP-SP-250-3.6-Al option 1”.

Standard aluminum case is suitable for water cooling. Alternative aluminum case (option 1) is suitable for both, conductive and water cooling.

Driver needs to be mounted on heatsink unless it is cooled by water. Driver's base plate temperature needs to be lower than 35 °C in all regimes of operation. Power consumption for 6 pF load.

Voltage or repetition rate derating is necessary if capacitance of your Pockels cell is higher. Contact vendor for details.

DP-SP series Pockels cell drivers can be used for single pulse selection in pulse picker applications for higher repetition rate lasers. While repetition rate can be up to 1 MHz, the standard range of possible pulse durations is from 15 ns to 5000 ns.

Features:

- Short circuit protection at driver output

- Driver pad overheat sensor stops operation when overheated

- Overheat optocoupled output signal

- LED for error indication (overheat and short circuit)

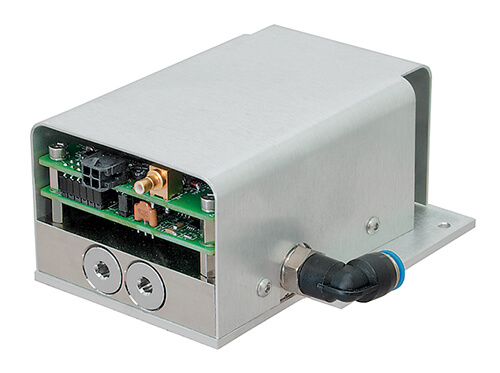

- Alternative aluminum case option featuring conductive cooling possibility and relocated water and HV output connectors (Option 1)

DP-SP series units are available in two versions: "open frame" which is ideal for OEM manufacturers incorporating drivers in their own systems and encased in aluminum housings. Encasing of Pockels cell driver in aluminum housing solves two problems: shields both humans and electronics from high voltage impact from operating Pockels cell driver, and protects driver itself from potentially harmful external contact - ensuring safe operation and driver longevity. The housed option is especially handy for researchers and custom product manufacturers who use these drivers during their own systems build-up.

- Address: Dvarcioniu st. 2B LT-10233 Vilnius, Lithuania

- Phone: (+370) 5 272 99 00

- Fax: (+370) 5 272 92 99

- E-mail: info@eksmaoptics.com

.png)

.png)