Products

Specifications

Brochures

Description

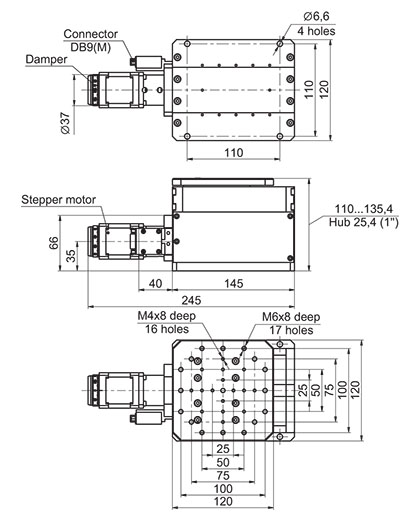

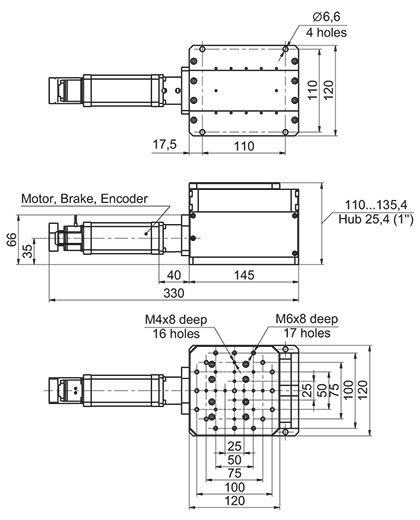

| 940-0218-01 | |

| Travel range | 25.4 mm (1 inch) |

| Resolution in full step | 5 µm |

| Resolution in 1/256 step | 0.019 µm* |

| Encoder pulses per revolution | by request |

| Lead srew pitch | 1 mm |

| Wedge reduction rate | 1 : 1 |

| Unidirectional Repeatability | 1.5 µm |

| Bidirectional Repeatability | 3 µm |

| Accuracy | 10 µm |

| Lift parallelisim | 35 µm (by request up to 15 µm) |

| Maximum speed | 20 mm/s |

| Maximum load capacity | 10 kg (15 kg by request) |

| Stepper motor | 4247 |

| Brake | By request |

| Optocoupler end limit switches | 2 |

| Switch polarity | Pushed is open |

| Motor connector | DB9(M) |

| Material | Aluminium |

| Finish | Black anodized hard cover |

| Weight | 4.05 kg |

* With 980-0045-USB controller.

| 940-0218 Precision Vertical Positioner

724.74 kB |

Motorized Vertical Positioning Stage 940-0218 provides high-precision positioning and smooth travel for loads up to 10 kg. Together with high quality linear bearing guide the system ensures rigid movement across all range of travel and long lifetime.

- True vertical elevation of the platform

- Compact design

- Long life time

- Vacuum compatible version available under request

Based on specifics of application other stepper motors or servos can be used. Stepper motor can be equipped with linear encoder and brake.

Products

Information

Eksma Optics

Contacts

- Address: Dvarcioniu st. 2B LT-10233 Vilnius, Lithuania

- Phone: (+370) 5 272 99 00

- Fax: (+370) 5 272 92 99

- E-mail: info@eksmaoptics.com

© 2025 EKSMA Optics, UAB. All rights reserved.