Products

Specifications

Description

Diameter

CT

Coating

Remove all filters

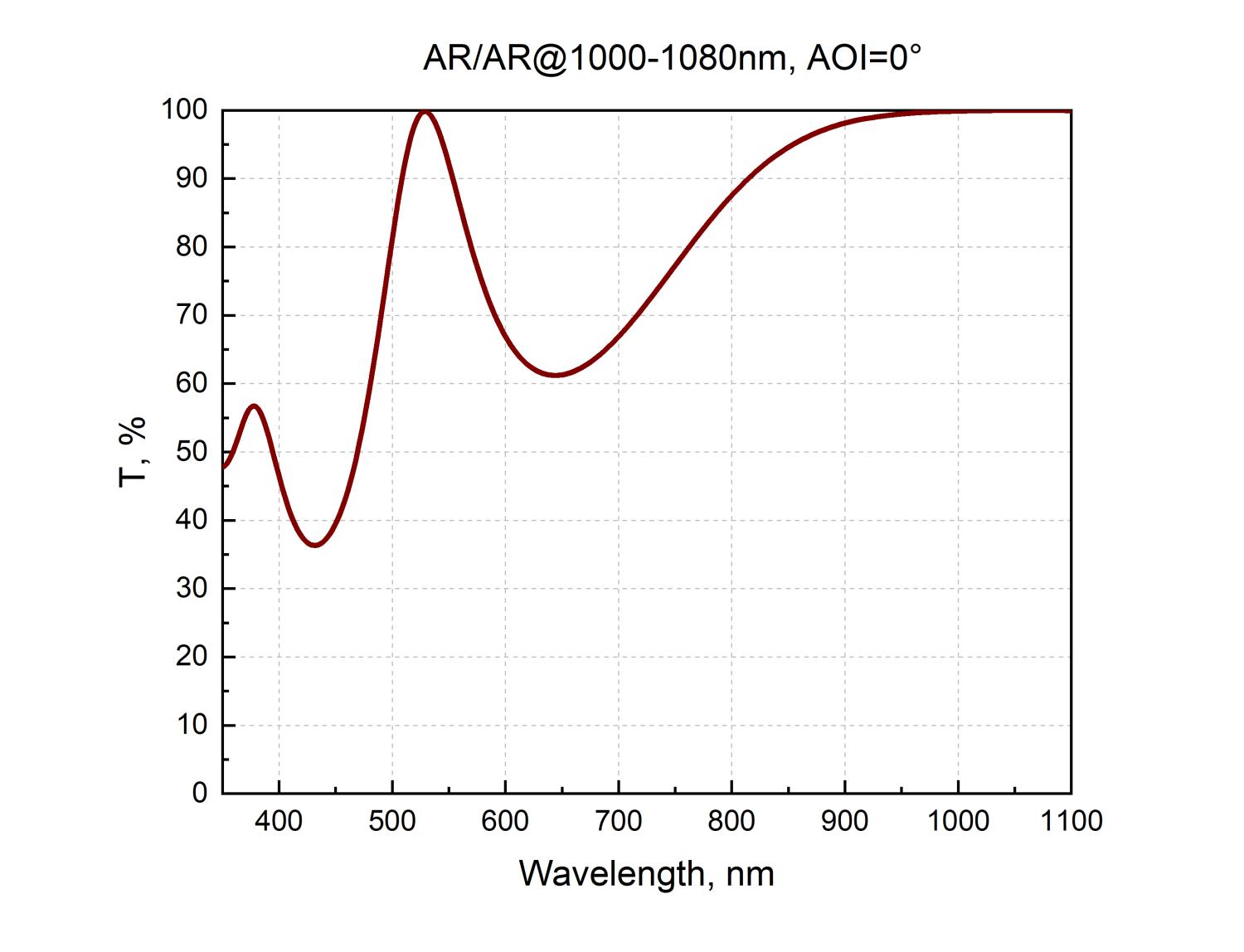

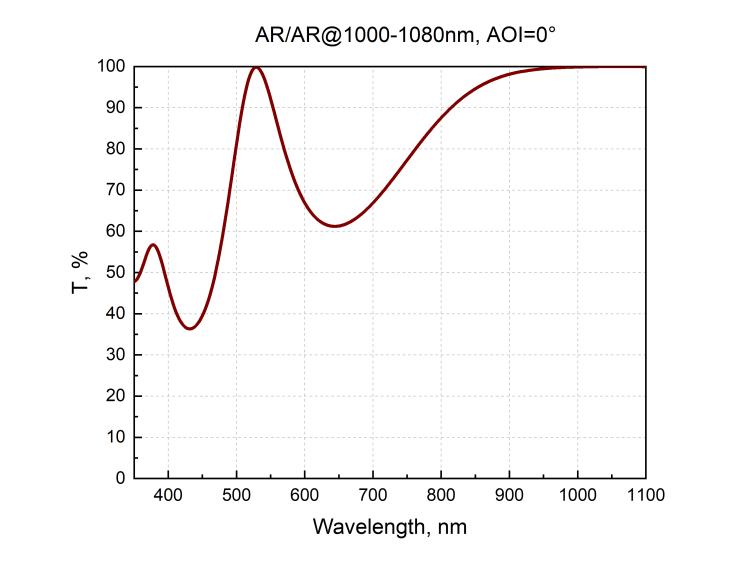

Convex-Aspheric Lenses with AR Coating @ 1000 - 1080 nm, R<0.1%

Uncoated Convex-Aspheric Lenses

SUBSTRATE SPECIFICATIONS

| Refractive index | Suprasil® – Nd=1.45846 |

| Design wavelength | 1030 nm (refractive index N=1.4496) |

| Surface quality | 40-20 scratch & dig (uncoated) |

| Clear aperture | >85% of diameter |

| Diameter tolerance | +0.0, -0.05 mm |

| Bevel | 0.3 mm max @ 45° |

| Center thickness tolerance | ≤0.05 mm |

| EFL tolerance | ≤0.1% |

| Asphere figure error P-V | ±1 µm |

| Surface form deviation RMS | ≤0.3 µm |

| Slope error | <0.3mrad/mm |

| Centration | <3 arc min |

COATING SPECIFICATIONS

| Technology | Ion Beam Sputtering |

| Adhesion and Durability | Per MIL-C-675A. Insoluble in lab solvents |

| Clear Aperture | Exceeds central 85% of diameter |

| Reflectivity at 1000-1080 nm | <0.1% at AOI=0-15° and <0.3% at AOI=15-33° |

| Damage Threshold | >560 mJ/cm2, 200 fsec pulse, 200 Hz, 1030 nm < >16M W/cm2 CW at 1070 nm, linear power density 172 kW/cm |

| Absorption in coating | <1 ppm at 1070 nm |

| Angle of incidence | 0-33° |

Features:

- Spherical and Coma aberrations corrected

- Back reflected light is divergent

- Substrate material absorption: <3 ppm/cm at 1064 nm

- Total metallic impurities: <1 ppm

- AR coating absorption at 1070 nm: ~0.5 ppm

CNC polished precision aspherical lenses are designed for diffraction-limited performance. We offer convex - aspherical lenses made of Suprasil specially designed to have the best performance and the highest laser induced damage threshold. The standard lenses can be supplied uncoated or anti-reflective coated at 1000-1080nm. Other coating regions are available according the request.

Products

Information

Eksma Optics

Contacts

- Address: Dvarcioniu st. 2B LT-10233 Vilnius, Lithuania

- Phone: (+370) 5 272 99 00

- Fax: (+370) 5 272 92 99

- E-mail: [email protected]

© 2026 EKSMA Optics, UAB. All rights reserved.