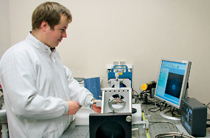

Quality Control Laboratory

All components are subject to high quality testing and certifications in Quality Control laboratory. Through stringent inspection procedures, quality control assessments and commitment to new advanced technologies, we are continuously improving and delivering exceptional quality.

The QC laboratory has vibration-isolated optical benches, laminar flow hoods and ultrasonic cleaners. It is equipped with high-precision measurement equipment to perform a wide variety of tests including:

- determination of optical and geometrical parameters, e.g. focal length, radius of curvature, crystals cut angles, optical axis or orientation determination, etc.;

- determination of polished surface quality according to MIL, ISO or DIN standards;

- flatness and wavefront distortion measurements (reflected or/and transmitted beams);

- prisms and wedges angles measurements and parallelism measurement of flat components;

- materials and thin-film coating spectral or/and angular reflectance and transmission.

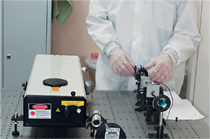

Optical Testing

- Analytik Jena spectrophotometer Specord®250 Plus for precise transmission and reflection measurements at 190-1100 nm range;

- Moeller-Wedel Optical Elcomat vario140/40 Autocollimator;

- EKSPLA laser spectrophotometer - for precise transmission and reflection measurements at 210-2300 nm range. Laser beam dia <1 mm;

- G-5 Goniometers - for prisms and wedged optics angles and flat components parallelism, piramidality measurements;

- ESDI Intellium Z100 Fizeau Interferometer - Computer controlled scientific interferometer for surface flatness and transmitted wavefront distortion measurements at 633 nm. Etalon accuracy lambda/20;

- Nikon Microscopes - x56-400 magnification microscopes with CCD cameras for surface quality inspection;

- EKSPLA NL220 laser - Nd:YAG laser operating at 1064, 532, 355, 266 for crystal cut angle accuracy checking, efficiency tests and orientation of crystals;

- Trioptics Super-Spherotronic HR Spherometer;

Laboratory capabilities

The Optics Laboratory has the following capabilities:

- determination of optical and geometrical parameters, e.g. focal length, refractive index, radius of curvature, angle, piramidality, determination of optical axis orientation for optimal wavelength conversion (2nd, 3rd harmonics generation);

- surface finish quality measurement, according to MIL, ISO or DIN standards;

- flatness measurements: wavefront distortion (reflected or/and transmitted beams);

- prisms and wedges angles measurements and parallelism measurement of flat components;

- materials and thin-film coating spectral or/and angular reflectance and transmission measurements (200-2300 nanometers);

- optical design, using ZEMAX software.

- Address: Dvarcioniu st. 2B LT-10233 Vilnius, Lithuania

- Phone: (+370) 5 272 99 00

- Fax: (+370) 5 272 92 99

- E-mail: info@eksmaoptics.com